1940 is the year when the first leather made product start to procure & produce in the land of Bangladesh. R.P. Saha is the man who dares to set up a tannery in Dhaka Metro at Narayanganj. Through his hand, this ambitious business starts to run and within a few years, it becomes an industry. Where people are starting to get employed and earn money. From Narayanganj leather factories and tanneries start to spread around the city. And Hazaribagh becomes the trade center of leather tanning, developing and procurement. Therefore, the buyers come here to buy raw hides and finished leather from here. And this how the leather sector in Bangladesh establish its footprints to the contribution of the national economy. Now we are going to explore the leather industry below:

Table of content:

- Tannery Zones

- Footwear Zone

- Leather Goods Zone

- Strength and Weakness

- Opportunities and Threats

- Conclusion

##Tannery Zone:

According to Wikipedia, a tannery is a place where the rawhides or skins are processed to produce leather. And tannery zones means where all the procurements, procedures and finishing of the are done. After products gather to distribute among the buyers.

Tanning hide into leather involves a process which permanently alters the protein structure of the skin, making it more durable and less susceptible to decomposition, and also possibly coloring it.

First of all, the Tannery Section is the key section for raw leather development. Cause tannery section collects the bulk amount of the rawhide during the Eid-ul-Adha. In the meantime, other festivals have a minor collection of rawhide And the types of leather export from Bangladesh are below:

- Crust Leather (Cow, Goat, Sheep, Buffalo in variety)

- Finished Leather (Cow, Goat, Sheep, Buffalo in variety)

- Split Leather in Wet Blue stage (Cow & Buffalo)

Crust Leather:

Basically, Leather which has been tanned but not finished is known as the crust leather. Because of its tannage, crust leather has a lot of variety. Here are the varieties mentioned below:

- Full Chrome Cow/Goat/Sheep/Buffalo Crust Leather

- Semi Chrome Cow/Goat/Sheep/Buffalo Crust Leather

- Full Vegetable Cow/Goat/Sheep/Buffalo Crust Leather

- Semi Vegetable Cow/Goat/Sheep/Buffalo Crust Leather

- 100% Chrome Free Full Vegetable Cow/Goat/Sheep/Buffalo Crust Leather

- Ecological (100% Chrome & Vegetable free) Cow/Goat/Sheep/Buffalo Crust Leather

- Full Chrome Cow/Goat/Sheep/Buffalo Lining Crust Leather

- Cow/Goat/Sheep/Buffalo Suede Crust Leather

- Cow/Goat/Sheep/Buffalo Nubuck Crust Leather

- Cow/Buffalo Split Suede Crust Leather etc.

Finished Leather:

First of all, there is a wide range of Finished Leather. In here we gather the names those are export from Bangladesh. And those are below:

- Polished Finished Leather

- Burnished Finished Leather

- Pigmented & Semi-Pigmented Finished Leather

- Aniline, Semi-Aniline & Semi-Aniline Nappa Finished Leather

- Glazed Finished Leather

- Milled Nappa Finished Leather

- Nubuck Finished Leather

- Water Proof Finished Leather

- Corrected/Plastic Finished Leather

- Pattern Finished Leather etc.

Split Leather:

Finally, the Split Leathers are exported by maintaining some criteria e.g. Size, Thickness, Tannage, with or without Shoulder or only Shoulder, etc. So, to make the thickness even, sometimes splits are exported after shaving. Normally, the following category (in Cow and Buffalo) splits are exported.

##In Cow:

- 5 SF+ Double Butt, 1.0 mm+ (without Shoulder)

- 5 SF+ Single Butt, 1.1 mm+ (without Shoulder)

- 7 SF+ Double Butt, 1.1 mm+ (without Shoulder)

- 7 SF+ Single Butt, 1.2 mm+ (without Shoulder)

- 10 SF+ Double Butt, 1.2 mm+ (without Shoulder)

- 10 SF+ Single Butt, 1.2 mm+ (without Shoulder)

- 7 SF+ Single Butt, 1.2 mm+ (with Shoulder)

- 9 SF+ Single Butt, 1.3 mm+ (with Shoulder)

- 10 SF+ Single Butt, 1.3 mm+ (with Shoulder)

- 12 SF+ Single Butt, 1.3 mm+ (with Shoulder)

- 12 SF+ Double Butt, 1.3 mm+ (with Shoulder)

- 2 SF+ Shoulder, 1.2 mm+

- 3 SF+ Shoulder, 1.3 mm+

- 4 SF+ Shoulder, 1.3 mm+ etc.

##In Buffalo

- 14 SF+ Single Butt, 1.6 mm+ (with Shoulder)

- 10 SF+ Single Butt, 1.8 mm+ (without Shoulder)

##Footwear:

Basically, leather has been introduced since 1940. By the time goes footwear industry is gradually popular in Bangladesh. And now it is the biggest opportunity for the footwear industry of Bangladesh to evolve more. And the journey of becoming a giant in this industry has already begun. So, we are now exploring the journey below:

First of all, Bangladesh has been positioned eighth as far as footwear generation on the planet in 2016. Cause we are creating 378 million sets of shoes or 1.6 percent of the aggregate yield, as indicated by World Footwear Yearbook 2017. And Bangladeshi footwear industry is one of the quickest developing on the planet. And expanding send out by about 700 percent amid the most recent decade, it noted. According to the EPB, during the first two months of the current financial year 2016–17, the country posted 23.62 percent growth in footwear exports over that during the same period a year ago.

#Footwear New Update:

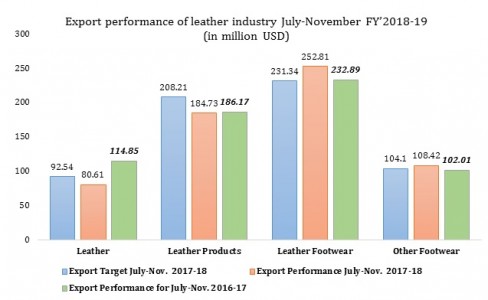

Another report by EPB, the overall export target of the leather and footwear industry was 636.19 million USD during FY’2018-19 (July- November). But it is underachieved by 9.62 million USD with an overall export performance of 626.57 million USD. The major decline happened in the leather category (HS code: 41). And a negative growth rate of -29.81% compared to the same period of last fiscal year (FY’2017-18). As a result, it only achieves export earnings of only 80.61 million USD. On the other hand, the projected export target was 92.54 million USD. The same thing happens in the leather goods category (HS code: 42-43). It also had a negative growth rate of -0.77% compared to the same period of last fiscal year (FY’2017-2018). So far it achieves export earnings of 184.73 million USD when the projected target was 208.21 million USD.

However, footwear (leather and non-leather) achieved positive growth. And leather footwear (HS Code: 6403) had a positive growth of 8.55% and export earnings was 252.81 million USD. As a result, 21.47 million surplus than the targeted export earnings. Also, non-leather footwear (excluding HS code: 6403) and footwear accessories achieved a positive growth rate of 6.28% as well. Total export earnings of 108.42 million USD. Also, earn 4.32 million surpluses compared to the targeted export earnings accordingly.

In addition, Bangladesh trades footwear to more than 50 nations, including the EU, China, Japan, Korea, Canada, and North America. Moreover, the EU is the biggest fare goal of Bangladesh’s footwear industry. Almost 54 percent is sent out to the EU showcase. However, Industry insiders to pick up a more prominent offer of the segment. So, Bangladeshi business visionaries should target both set up top markets.

##Leather Goods:

According to industry inside currently, 220 tanneries, 2500 footwear manufacturing units and 90 large firms are involving in the leather and leather goods sector. However, this sector is contributing 4% to the country’s total export earnings by exporting items to more than 50 countries. So, the exports will increase manifolds if the leather and leather goods sector meet the compliance standards and take initiatives to promote their products in the international market. At present, we earn about US$ 1.23 billion by exporting various leather products in FY2016-2017. And the government, however, has set a target to earn $5.0 billion from exporting leather, leather goods, and the footwear sector as part of the $60 billion overall export earnings by 2021.

Strength & Weakness:

- High growth and investment potential

- Availability of highly reputed, high-quality leather

- Government’s thrust as a priority sector—provision of incentives and exporter-friendly policies

- A large pool of inexpensive manpower

- Insufficient use of better technologies and appropriate

- production methods

- Lack of R&D and training

- Dependence on expensive imported raw materials.

- Inefficient raw material procurement and firms’ lack of market information, and knowledge of business promotion opportunities and marketing strategies

- Difficulty in obtaining bank loans

Opportunities & Threats:

- Potential to replicate RMG success story.

- Large and growing global leather export market and increasing demand for Bangladesh’s leather-based products.

- Rising potential in the domestic market.

- Leather exports gaining momentum in recent years.

- Large demand in emerging markets.

- Establishment and promotion of economic zones all over the country.

- Placement of new tannery estate in Savar.

- Stricter international standards

- Stiff competition from other Asian economies

- Lifting of trade preferential treatment in the near future

- High costs of doing business

Final Words:

Currently, in 2018, the sector has already started changing. First of all, the tanneries are moving Savar from Hazaribagh. In Savar, tanneries are getting larger space, healthy work environment, better water & electricity supply, etc. And now the tanners & manufacturers are also moving to this area. Yet there are few problems arrive on this moving time. Meanwhile, some of them are not moving on time, expected facilities are not provided properly, No hot water facilities, and so on. That’s why few drops on production make the industry analyzers anxious. But every progressive move has some difficulties & hinders on their way of success. So, we are also hopeful with our change and adaptability of our leather industry. And we are on the way to our destination.

Leave a Reply